Torsion Axles on 8.5x14 Double Enclosed Trailer

Upgrade your 8.5x14 tandem enclosed trailer with independent suspension for quieter towing, less bounce, steadier tracking, and protected cargo on every trip.

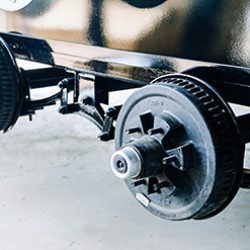

These are example photos of the Torsion Axles on 8.5x12 Double Enclosed Trailer with standard features, for more information on custom options. please visit our custom option page.

Technical Features

Torsion Axles on 8.5x14 Double Enclosed Trailer

→ → →

| Standard Features | South Georgia Cargo |

| PRICE | $6,620.00 |

| EXTERIOR METAL | White or Black metal exterior (.080) /Screwed metal exterior |

| AXLES | 3500lb spring axles with 4" drop |

| V-NOSE | V-Nose with vertical ATP trim |

| ELECTRIC BRAKES | Axles w/ Electric Brakes |

| DOME LIGHT | (2) 12V Dome lights with switch |

| WALLS/CEILING TUBING | 1x1" steel tube in walls and ceiling |

| FLOOR TUBING | 6 I-Beam Main Rails |

| FLOOR CROSS-MEMBERS | 16" OC Floor Members |

| ROOF CROSS-MEMBERS | 24" OC Roof Members |

| WALL CROSS-MEMBERS | 16" OC Wall Members |

| LIGHTS | LED Exterior Lights / LED Strip tail lights |

| INTERIOR HEIGHT | 6'6" (78") Interior Height |

| REAR DOOR | Rear Ramp with spring Assists & Extension Flap |

| PLUG / COUPLER (BALL) | 7-way Round elec. Plug / 2 5 / 16"coupler. |

| FENDERS | Aluminum fenders w/lights |

| SIDE DOOR | 36" RV style side door with flush lock |

| ATP | ATP in Stepwell |

| TIRES | 205-15 Radial Tires |

| RIMS/WHEELS | Silver Mod Wheels |

| ROOF MATERIAL | Galvalume roof |

| STONEGUARD | 24" Stoneguard on front |

| TONGUE JACK | 2000 lb tongue jack |

| HUBS | EZ Lube Hubs |

| THERMA-PLY | ❌ |

| WALL MATERIAL | Premium 3/8" plywood sidewalls |

| FLOOR MATERIAL | 3/4" plywood floor/Painted Underneath |

| SIDEWALL VENTS | Non-powered roof vent |

| DRINGS | (4) floor D-rings |

| EMPTY WEIGHT | 2700 lbs |

| LOAD CAPACITY | 4300 lbs |

| GVWR | 7000 lbs |

| TONGUE WEIGHT | 402 lbs |

Available Colors

Click the color of your preference to see a sample photo of an enclosed trailer

Create a Quote

The quote will outline standard features and custom option pricing separately and can be adjusted as needed before the order is placed.

Enjoy a Smoother Ride with Torsion Axles on 8.5x14 Tandem Enclosed Trailer

When you invest in a versatile workhorse like an 8.5x14 tandem enclosed trailer, every component matters. This isn’t just a box on wheels; it’s a mobile workshop, a vehicle hauler, or a secure transport for your most valuable equipment. While features like a sturdy main frame and bright LED lights are crucial, the unseen component that dictates the quality of your towing experience is the suspension system. As the global trailer market continues to expand, discerning buyers are increasingly looking beyond standard features to components that offer superior performance and long-term value. This is where torsion axles enter the conversation, transforming a good cargo trailer into an exceptional one by delivering a smoother ride and lasting durability.

Introduction: Elevating Your Hauling Experience with Torsion Axles

The Importance of Trailer Suspension for Your 8.5x14 Tandem Enclosed Trailer

The suspension system on your tandem axle enclosed cargo trailer is the critical link between the road and your cargo. It’s responsible for absorbing shocks, dampening vibrations, and maintaining tire contact with the pavement. A subpar suspension translates directly to a rough, unstable ride that not only stresses the trailer’s structure but also puts your valuable cargo at risk. For a trailer of this size, often tasked with heavy or delicate loads, the choice between standard spring axles and advanced torsion axles is a decision that impacts everything from cargo safety to driver comfort.

Why a Smoother Ride and Lasting Durability Matter for Your Cargo

Imagine towing a classic car, expensive machinery, or a trailer full of sensitive electronics. Every pothole, bump, and uneven road surface sends a jolt through a traditional suspension system, vibrating through the frame and into your cargo. This constant agitation can lead to damage, load shifting, and premature wear on both the items being hauled and the enclosed trailer itself. A smoother ride isn’t a luxury; it’s an insurance policy for your assets. Likewise, durability is paramount. A suspension system that requires frequent maintenance or fails prematurely results in costly downtime and repairs, directly impacting your bottom line. Torsion axles address both of these concerns at their core.

Understanding the 8.5x14 Tandem Enclosed Trailer

Common Uses and Demands of This Trailer Size

The 8.5x14 tandem enclosed trailer is a popular choice due to its ideal balance of maneuverability and substantial payload capacity. Its dimensions make it perfect for a wide range of applications:

- Contractors and Landscapers: Hauling tools, mowers, and heavy equipment. A Flat Front Landscape Cargo Trailer variant is specifically designed for these needs.

- Motorsports Enthusiasts: Transporting cars, ATVs, motorcycles, and gear.

- Mobile Businesses: Serving as mobile offices, concession stands, or workshops.

- General Hauling: Moving furniture, antiques, or large-scale project materials.

These demanding uses mean the trailer must withstand significant weight, frequent use, and varied road conditions, placing immense stress on its suspension.

The Role of Tandem Axles in Weight Distribution and Stability

The use of tandem axles, as opposed to a single axle, is fundamental to the capability of an 8.5x14 enclosed cargo trailer. This dual-axle configuration distributes the trailer’s weight over four wheels instead of two, significantly increasing its stability and payload capacity. Market data shows that the tandem axle segment dominated the trailer axle market due to this superior load distribution. This setup reduces the tongue weight on the tow vehicle, enhances braking performance—especially when equipped with electric brakes on both axles—and provides a critical safety redundancy; if one tire fails, the other on the same side can temporarily support the load.

What Makes This Specific Trailer Configuration Prime for Advanced Suspension

An 8.5x14 tandem axle trailer is the perfect candidate for a torsion axle upgrade precisely because of its demanding applications. The heavy loads and valuable cargo it typically carries benefit immensely from superior shock absorption. The increased stability offered by tandem axles is further amplified by the independent suspension characteristic of a torsion system, reducing trailer sway and improving overall handling. When you invest in a trailer of this caliber, optimizing its core performance with an advanced suspension system is a logical and valuable step.

What Are Torsion Axles? Debunking the Technology

Independent Suspension Explained: How Torsion Axles Differ

Unlike traditional spring axles that connect both wheels on a solid beam, torsion axles provide a form of independent suspension. Each wheel is attached to its own torsion arm, which can move up and down independently of the wheel on the opposite side. This means that when one wheel hits a pothole, the shock is absorbed by that specific wheel’s suspension without being directly transferred across the axle to the other wheel and the trailer frame. This decoupling of wheel movement is the fundamental reason torsion axles deliver a significantly smoother ride.

The Inner Workings: Rubber Torsion Arms and Their Function

The “magic” of a torsion axle happens inside the main axle tube. The tube is typically square or hexagonal and contains long rubber cords or cartridges. The torsion arm, which connects to the wheel spindle, is fitted into this tube. As the wheel moves over a bump, the torsion arm rotates, compressing the rubber cords inside the axle tube. This compression of the rubber absorbs the road shock and dampens vibrations. The natural elasticity of the rubber then returns the arm to its neutral position. It’s a simple, elegant design with very few external moving parts.

Key Components: Spindles, Hubs, and the Axle Beam

While the internal rubber is the core of the technology, a torsion axle system comprises several key components. The main axle beam provides the structural housing. The torsion arms transfer the force from the wheels to the rubber cords. At the end of each arm are the spindles, which the wheel hubs and bearings mount onto. These hubs are often equipped with electric brakes for reliable stopping power. The entire assembly is a self-contained unit that bolts directly to the trailer’s main frame, creating a clean, low-profile setup. The growth of the global automotive axle market reflects ongoing innovation in designs like these that prioritize performance and efficiency.

Torsion Axles vs. Traditional Spring Axles: A Critical Comparison

How Spring Axles Work (Leaf Springs and Shock Absorption)

The most common and traditional suspension system is the spring axle. This design uses stacks of curved steel plates, known as leaf springs, mounted between the trailer frame and the axle. When the trailer hits a bump, the leaf springs flex to absorb the impact. They are a time-tested, relatively inexpensive, and easily repairable technology. However, their design inherently links the wheels on both sides, meaning an impact on one side is partially transferred to the other, leading to a bouncier ride.

Core Differences in Design and Functionality

The fundamental difference lies in the mechanism of shock absorption and wheel independence.

- Torsion Axles: Use internal rubber compression and provide independent wheel movement.

- Spring Axles: Use external steel leaf springs and function as a solid-axle system.

This design difference leads to significant variations in performance. Torsion axles offer a quieter, smoother ride because there is no metal-on-metal contact from leaf springs. They also typically allow for a lower deck height, which can make loading and unloading easier through the side door or rear ramp.

Direct Comparison Table (Conceptual: for content, not outline header)

When weighing the options, a direct comparison is helpful. Torsion axles excel in ride quality, offering superior vibration dampening that protects sensitive cargo. They have fewer moving parts, which translates to minimal maintenance. Spring axles, while providing a rougher ride, are generally less expensive upfront and are easier to repair or replace in the field due to the widespread availability of parts. In terms of durability, the self-contained, weather-resistant design of torsion axles often gives them an edge over exposed leaf springs, which are susceptible to rust and wear.

Addressing Common Misconceptions About Both Systems

A common misconception is that torsion axles have a lower payload capacity. This is incorrect; torsion axles are available in the same weight ratings as spring axles, perfectly capable of handling the demands of a tandem axle setup. Another myth is that they are impossible to repair. While it’s true that a failed torsion axle typically requires a full replacement rather than a simple spring swap, their failure rate is significantly lower due to their robust, simple design. Conversely, while spring axles are easily repaired, they also require more frequent maintenance, such as checking and replacing shackles and bushings.

The Unmistakable Benefits: A Significantly Smoother Ride

Superior Shock Absorption and Vibration Dampening

The rubber dampening system inside a torsion axle is inherently superior at absorbing high-frequency vibrations from the road compared to the flexing steel of a leaf spring. This results in a ride that is not just less bumpy, but also quieter and more stable. The trailer feels more connected to the tow vehicle, and the constant chatter and vibration common with spring axles are virtually eliminated.

Protecting Your Valuable Cargo: From Delicate Goods to Classic Cars

This superior ride quality is a direct benefit to your cargo. For contractors, tools with sensitive calibration remain accurate. For motorsports enthusiasts, custom vehicles are protected from undue stress on their own suspension components. For businesses moving electronics or furniture, the risk of damage from transit is drastically reduced. An enclosed cargo trailer with torsion axles provides a more stable environment, ensuring your assets arrive in the same condition they left.

Enhanced Handling and Control for the Driver (Reduced Trailer Sway)

The independent suspension of torsion axles contributes to better handling and reduced trailer sway. Because a jolt on one side doesn’t upset the entire trailer, it tracks more smoothly behind the tow vehicle, especially in crosswinds or on uneven roads. This stability is a critical safety feature, as data from the National Highway Traffic Safety Administration underscores the ongoing need for improved safety measures in towing. When paired with high-quality radial tires and reliable electric brakes, a torsion axle system provides the driver with greater confidence and control.

Minimizing Road Noise and Driver Fatigue

The constant noise and vibration transmitted from a trailer with spring axles can be a significant source of driver fatigue on long hauls. Torsion axles, by isolating the trailer body from much of this road harshness, create a quieter and more pleasant towing experience. Arriving at your destination feeling less worn out is a tangible benefit that is often overlooked but greatly appreciated by anyone who spends significant time on the road.

The Unmistakable Benefits: Enhanced Durability and Longevity

Reduced Wear and Tear on Trailer Components (Frame, Welds, Fasteners)

The constant vibration from a rough suspension system takes a toll on the entire cargo trailer. It stresses welds on the main frame, loosens fasteners on features like a Screwless Exterior, and can cause fatigue in structural components over time. By dampening these vibrations at the source, torsion axles reduce the overall stress on the trailer, contributing to a longer service life for the entire unit, from the triple tube tongue to the rear ramp door.

Fewer Moving Parts Mean Less Maintenance and Potential Failure Points

A spring suspension system has multiple wear points: the springs themselves, shackles, bolts, and bushings. These components require periodic inspection, lubrication, and eventual replacement. Torsion axles eliminate all these external moving parts. With no shackles to wear out or springs to break, the system is virtually maintenance-free, a significant advantage when considering that maintenance and repair costs for trucking rose by 3.1 percent in 2023. This simplicity translates directly to fewer potential failure points and greater reliability.

Corrosion Resistance (Elimination of Leaf Springs)

Leaf springs are stacks of steel plates that are constantly flexing and exposed to the elements. This makes them highly susceptible to rust, which can build up between the leaves, hindering their performance and eventually leading to failure. The enclosed design of a torsion axle protects its core components from water, salt, and road grime, offering superior corrosion resistance and performance longevity, especially in harsh climates.

Maintaining Payload Capacity and Performance Over Time

Leaf springs can sag over time with heavy use, which can reduce the trailer’s ride height and affect its payload capacity and handling characteristics. The rubber compounds in torsion axles are engineered to resist setting and fatigue, allowing them to maintain their performance and support the trailer’s rated payload capacity consistently throughout their long service life.

Beyond the Ride and Durability: Additional Advantages

Lower Profile and Ride Height (Easier Loading/Unloading)

Torsion axles can be configured with various start angles for the torsion arm, which allows for a lower ride height compared to a traditional spring axle setup. This lower deck makes loading and unloading heavy equipment or vehicles via a ramp door significantly easier and safer due to the reduced incline angle. It can also improve the trailer’s aerodynamics and center of gravity, contributing to better fuel efficiency and stability. When considering custom options like an RV DOOR or specialized loading lights, a lower profile enhances overall accessibility and usability.

When you’re ready to invest in a superior towing experience, working with a knowledgeable production team is key. Opting to Build Your Own Trailer allows you to specify a torsion axle upgrade from the start, pairing it with other premium custom options. Consider enhancements like stylish Liger Aluminum rims, a spare tire with a mount for peace of mind, or an upgraded Electrical Package to power a 15,000 BTU A/C with Heat Strip. A comprehensive LED light upgrade connected via a reliable 7-way Round plug ensures your trailer is safe and visible. Making torsion axles a foundational choice in your custom build is an investment in performance that pays dividends on every mile of the journey.

Conclusion

Choosing the right suspension is one of the most impactful decisions you can make for your 8.5x14 tandem enclosed trailer. While traditional spring axles have served the industry for decades, torsion axles represent a significant technological advancement that delivers tangible benefits. By providing a dramatically smoother ride, they protect your valuable cargo, reduce wear and tear on the entire trailer structure, and minimize driver fatigue. Their simple, robust design with fewer moving parts leads to enhanced durability, lower maintenance requirements, and greater long-term reliability.

Whether you are a contractor protecting your tools, a racer hauling your prized vehicle, or a business owner relying on your mobile setup, upgrading to torsion axles is a strategic investment in safety, efficiency, and peace of mind. As you specify your next cargo trailer, look beyond the surface features and consider the foundational component that will define your hauling experience. Opting for torsion axles ensures your trailer is not only built to carry your load but also engineered to protect it for years to come.

Ready to Purchase?

Pay Deposit Here

By clicking Buy Now, you will be redirected to our secure PayPal checkout page. A deposit is required to reserve the standard version of this trailer size. The remaining balance, including any selected options or upgrades (such as A/C or insulation), will be due at pickup or delivery. Final price may vary depending on manufacturer and features. Please Contact Us to confirm details before completing your order.

Have you recently invested in an enclosed cargo trailer, or are you looking to maximize the lifespan and efficiency of your current one? Our comprehensive PDF guide is your ultimate companion to mastering the art of trailer maintenance!

- Step-by-step instructions on pre-use checks to ensure safety and readiness for the road.

- Expert advice on periodic maintenance routines to keep your trailer in peak condition.

- DIY tips for interior and exterior care, from flooring maintenance to rust prevention.

- Winterizing strategies that protect your investment through the coldest months.

- Essential insights into tire care, brake maintenance, and the importance of proper ventilation.

- Bonus content: Safety equipment checklist, emergency preparedness, and much more!

Safeguard Your Investment:

10 Smart Ways to Prevent Trailer Theft!

Reviews for the Torsion Axles on 8.5x14 Double Enclosed Trailer